IMPRES Battery Fleet Management

In its basic form, an IMPRES system consists of a smart battery working together with a smart charger and radio, that are able to access the information stored in the battery's on-board charge management chipset. The charger would read this data and make a decision on what to do when the battery is inserted. The radio is also able to access this data and would give the user an indication of the battery's state of charge and health.[1]

IMPRES batteries offer two significant advantages over non-IMPRES batteries. Information about the state of charge is readily available when a battery is inserted into the charger. This is important because battery voltage is not a very good indicator of state of charge, since the voltage of a discharged battery can increase if the battery is allowed to rest for a while - even though it is depleted. Non-IMPRES chargers would either charge anything inserted into the charger or take a voltage measurement then start charging until the current drops.

Also, by reading the state-of-charge information in the on-board IMPRES battery memory, the charger can determine which action is needed to prolong the service life of the battery. For example, a battery that was recently charged, but never used, does not need to be charged again. Or, a battery that has been discharged and not charged for a while may need to be reconditioned. The IMPRES charger has a microprocessor and software which allow it to communicate with the battery IMPRES chipset.

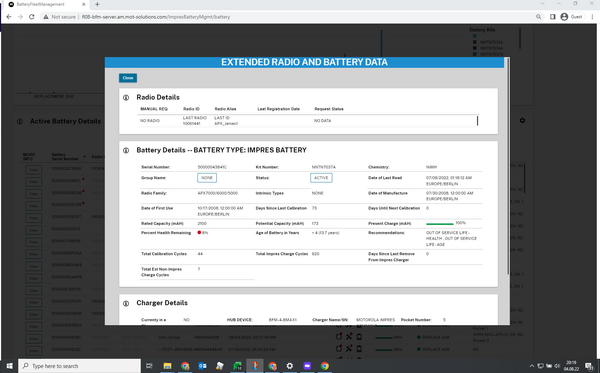

IMPRES batteries also store the number of charge-discharge cycles, allowing the end of service life to be easily determined. Each time the battery is charged; reconditioned or attached to a radio, information about the activity is written to the battery IMPRES memory.

IMPRES Battery Fleet Management

For customers with a large fleet of radios scattered across multiple locations, keeping an eye on deployed batteries can be a nightmare. To address this problem, Motorola Solutions developed IMPRES Battery Fleet Management, an application that gathers information from all the IMPRES batteries used on their system.

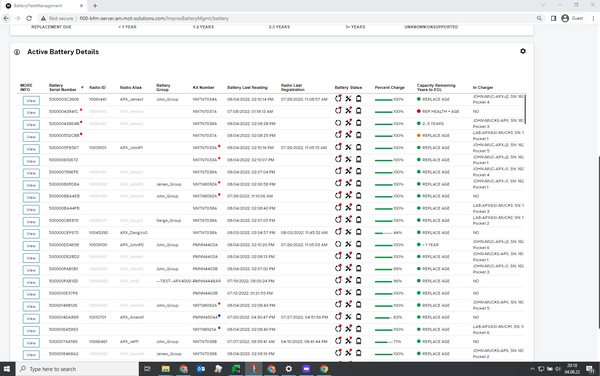

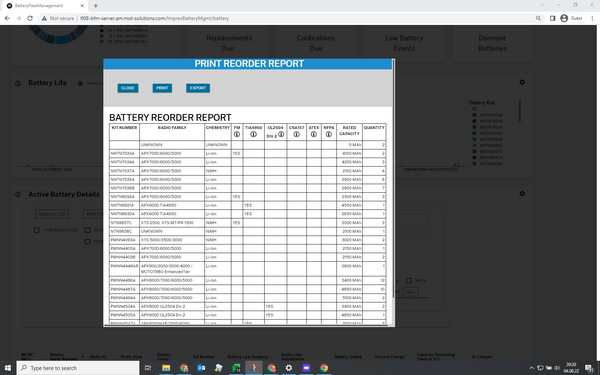

The state of health information presented by this software allows customers to quickly and easily screen batteries and determine which need to be replaced and when.

Each IMPRES battery has a unique serial number that can be used to identify it and which radio it is attached to. When a battery is due for replacement, the user in whose possession it is, can be alerted to come past and get a new battery for their radio.

Because a lot of the guesswork is eliminated, customers can save money by only replacing batteries that can no longer perform. Not only that, customers and channel partners can start applying JIT and MRP to their stockholding of IMPRES batteries since the replacement date is known before problems arise.

Motorola Solutions have just released a new version of IMPRES Battery Fleet Management. The user interface has undergone a complete redesign and is now web-based.

The IMPRES Battery Fleet Management software gathers battery data in two ways:

- Over the air.

- By means of an IMPRES multi-unit charger, connected to the PC via USB (and ethernet via a proxy).

Using either a control station or MNIS, the software is able to gather state of health information from all connected batteries over time, thereby constructing current information about battery status.

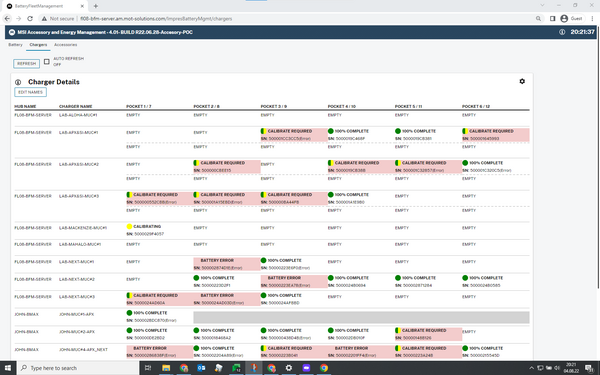

There are essentially two types of IMPRES chargers: A single unit charger with LED indicator (see above) and a Multi-Unit Charger with one or more displays. Currently, only the multi-unit charger can be connected to battery fleet management. Older versions of the IMPRES multi-unit charger require a charger interface unit (which is no longer sold but still supported by the software) to connect to a PC. The current version of IMPRES multi-unit charger can connect directly to the PC via USB. Incidentally, these (new) multi-unit chargers can also charge and discharge batteries to 50% capacity so that they can be stored for longer periods or transported by air. Up to 25 IMPRES multi-unit chargers can be connected to a PC and up to 20 PCs can be connected via IP to a central server (PC) which means hundreds of multi-unit charger chargers, at remote locations, can be connected into IMPRES Battery Fleet Management.

Information that the software provides

| |

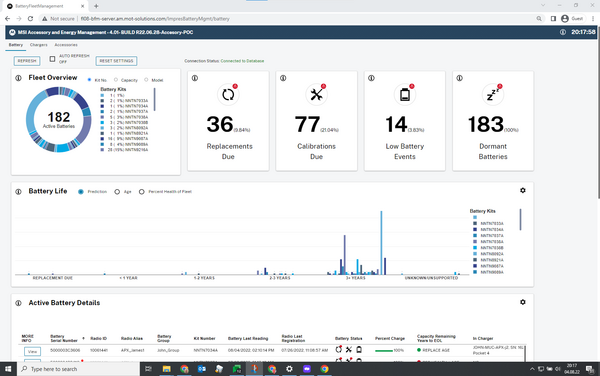

IMPRES Battery Fleet Management is accessed using a web browser which means the users can access battery information using a standard web browser. The home page shows vital information about all the IMPRES batteries used on the system:

- How many batteries of each model.

- How many need calibration (calibration is done on an IMPRES charger),

- How old these batteries are or how many are due for replacement and when.

- How many batteries have gone AWOL.

- How many batteries are running flat.

Deployment and Communication

The application consists of a Client, a Server, and a Proxy. It communicates with the radio system through an IP data gateway, which can be either the Motorola Solutions Network Interface Service (MNIS) or a mobile radio configured as a Control Station. Battery Fleet Management sends IPv4 data messages to radios and is designed to be agnostic to the underlying radio system architecture (e.g., conventional, IP Site Connect, Capacity Plus, Capacity Max) or the type of data gateway used. The application and MNIS can reside on the same PC or different PCs. If on separate PCs, a static IPv4 route is necessary on the BFM PC to direct radio data through the MNIS, and the MNIS's UDP port (default 4012) must be forwarded to the BFM PC's IPv4 address. These PCs should ideally be in the same subnet. While BFM itself doesn't require the Device Discovery and Mobility Service (DDMS) for its operation, MNIS does require DDMS to route data to the appropriate channel and site.

OTA battery management messaging does not revert to other channels. Therefore, the BFM IP data gateways do not need to monitor revert channels. The IP data gateway used by BFM must be configured for confirmed data calls to ensure a high success rate for OTA battery management messages. All prerequisites and limitations of the standard MOTOTRBO IP data service apply to IMPRES Battery Fleet Management.

System-Level Optimizations and Considerations

The Battery Data Refresh Timer controls how often battery data is read. Its default value is 21 days (3 weeks). Reading data more frequently can increase the load on the system, especially with a large number of radios.

The Radio Hold Off Timer dictates how long a radio waits after powering up before registering its battery with BFM (default 2 hours). Increasing this value can help minimize OTA message collisions and network congestion, particularly during events like shift changes when many radios are powered on simultaneously.

When a radio is powered on and placed in a charger, its battery data cannot be collected OTA. The automatic collection process pauses and resumes once the radio is removed from the charger. Radios in chargers will not respond to manual battery data read requests OTA.

Software and licences

The software can be downloaded from here. A software licence is required to use the software for more than 30 days. As of 8 August 2022, there is no charge for the software licence in EMEA.

| Part Number | Region |

|---|---|

| HKVN4036 | North America |

| HKVN4037 | EMEA |

| HKVN4038 | Latin America |

| HKVN4039 | Asia |

See Also

References

- ↑ Motorola Solutions' best kept non-secret. Retrieved 07.07.2025.